inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980

inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980Henan Kino Cranes Co., Ltd

No.730, Xinghai Center, Hongqi District, Xinxiang, Henan, China

Tel: +86-373-3809941

M/P: +86-15993036980

E-mail: inquiry@kinocranes.com

Official Website: www.kinocranes.com

Construction winch is used for operations such as winching and towing heavy things, erecting equipment, piles driving, and coldly pulling reinforcing steel bar in such industries as constructions, metallurgy, mines, weight lifting. The working surroundings to which the winch is applicable are: temperature -10℃~+40℃ ( when surrounding temperature is below 0℃, before start-up, lubricating oil should be heated up), humidity ≤85%,altitude below 1000m, no fire and explosion accident and so on. It uses 380V,50Hz, 3-phase alternating current power supply and ±5% tolerable voltage difference. Working grades of winch in use are M4 or M5; when increasing every grade working grade, its rated pull should correspondingly reduce 20%.

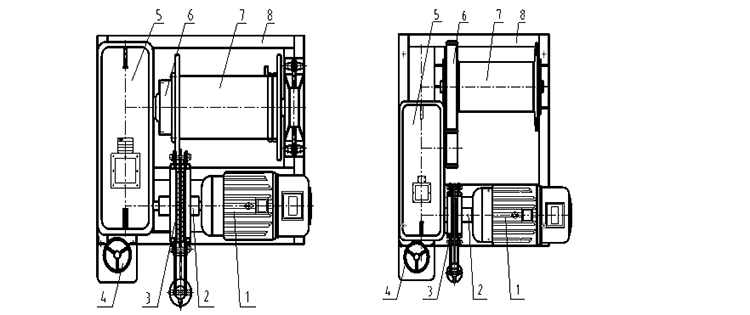

Structure and working principle:

Electrically-controlled winch implements its operations or braking through connecting or disconnecting power supply.When connecting electrical source, band-type brake of normally-closed brake arrester will loose; electromotor starts up; Then shaft coupling drives speed retarder; After reducing the speed of the speed retarder, through the drive of connecting tray or open-style gear wheel, the reeling drum starts to work. When stopping machine, disconnect electrical source and normally-closed brake arrester will hold the braking wheel to make the reeling drum stop revolving, then the winch stops its running. Rising or falling of materials is reached through clockwise revolving and counterclo.

ckwise revolving.

Installation and Testing:

1. When installing, dismantling and moving the winch, it is necessary to keep stable and being not overly oblique without any clashes and fierce vibration.

2. Installation of winch

Its installation should be completed by professionals. The ground for installing the winch should be leveled off and much solid. The connection between winch and base should be reliable.

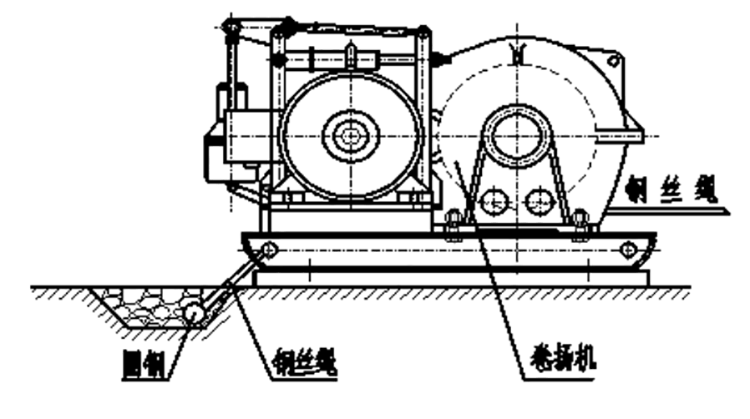

2.1 When mobile using, fix the winch to timber sleepers block, and reliably and tightly connect timber block and chassis to ground anchor with steel wire rope. Be aware of avoiding any looseness.(See Figure 3)

Care and maintenance:

1. The driving part of the winch, such as the drum bearing, the brake hinge and the shaft pin of each part, lubricated once before each shift operation; Guide pulley, wire rope lubrication for 48 hours; The height of the lubricating oil level in the reducer box should be within the scope of the dipstick scale. Under normal operating conditions, it should be checked once a week and replaced once every six months.

2. Winch work 300 hours, a level maintenance, re-lubrication of the whole machine, check and adjust the brake, check the reducer, replace or add new lubricating oil to the specified oil level height.

3. Winch works 600 hours in total, carries out secondary maintenance, and determines the insulation resistance of the motor; Check the wear of friction surface, gear bearings, rotating parts, connectors and electrical components, etc., if the machine is affected, it should be replaced in time.

4 every day should be winch operation record in the operation table, record content including: daily working time, load and inspection, repair, adjustment and so on.