inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980

inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980Henan Kino Cranes Co., Ltd

No.730, Xinghai Center, Hongqi District, Xinxiang, Henan, China

Tel: +86-373-3809941

M/P: +86-15993036980

E-mail: inquiry@kinocranes.com

Official Website: www.kinocranes.com

Single-speed electric hoist

A single-speed electric hoist has only one lifting motor, with a single lifting speed, which is the constant speed. The lifting speed varies depending on the tonnage, and the model is represented by the CD1 type.

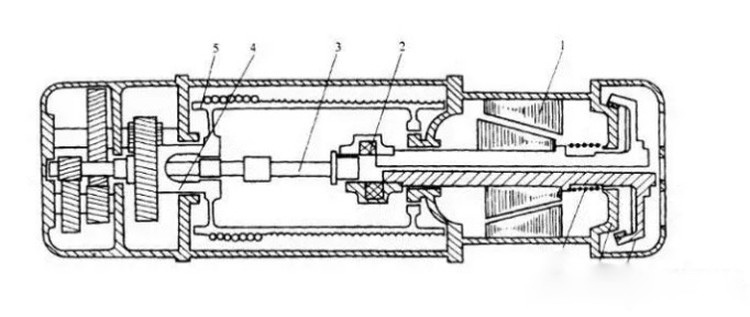

Working principle of CD type electric hoist:

In the figure, the upper and lower positions of the motor rotor represent the situations of power off and power on respectively. The position of the brake wheel 8 is on the right side of the motor. When the motor is powered, the rotor moves to the right, opening the brake. The transmission route is from the motor, coupling, input shaft 3 of the three-stage gear reducer, output shaft 4 of the reducer, to the wire rope drum 5.

Dual-speed electric hoist

A dual-speed electric hoist has a small accelerating motor connected to the main motor with a belt next to the main lifting motor. When the main motor rotates, the small motor rotates faster, thereby increasing the lifting speed. The main motor operates at a constant speed, while the auxiliary motor operates at a slower speed. The model is represented by the MD1 type.

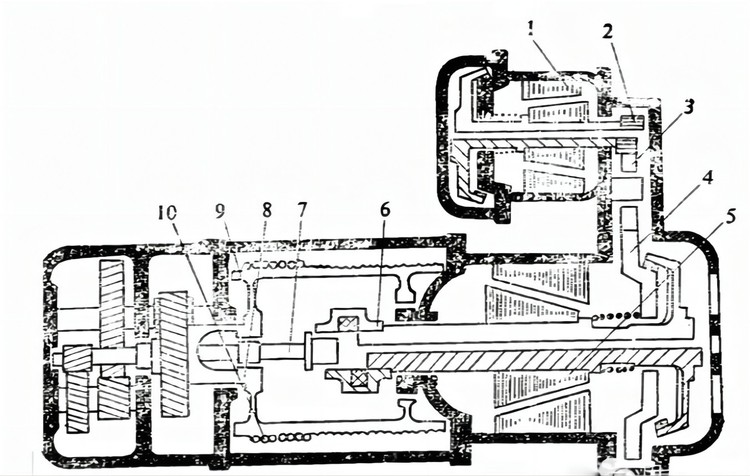

Working principle of MD1 type electric hoist:

1- Lifting auxiliary machine

2- Small gear

3- Intermediate gear

4- Large gear

5- Main motor rotor

6- Coupling

7- Input shaft

8- Hollow shaft sleeve

9- Drum

10- Wire rope

During slow-speed operation, the auxiliary machine 1 is powered, causing the small gear 2, intermediate gear 3, and large gear 4 to rotate, thus rotating the rotor of the lifting main engine 5, and then driving the drum through the coupling. The three-stage gear reducer drives the wire rope drum to lift objects;

During constant-speed operation, the lifting auxiliary machine 1 is not powered, and the small gear 2, intermediate gear 3, and large gear 4 remain stationary. The lifting main motor 5 is released from the brake state and drives the drum 9 through the coupling 6 and the three-stage gear reducer to lift objects.

Dual-speed electric hoists are commonly used in assembly workshops, where the slow speed allows for more precise positioning during descent and ensures a more balanced lifting of products.