inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980

inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980Henan Kino Cranes Co., Ltd

No.730, Xinghai Center, Hongqi District, Xinxiang, Henan, China

Tel: +86-373-3809941

M/P: +86-15993036980

E-mail: inquiry@kinocranes.com

Official Website: www.kinocranes.com

The practical significance of European crane anti-sway technology

The wrong operation of the moving direction, the rapid change of the moving direction, the sudden start or stop of the crane, and the acceleration or deceleration during operation will cause the hoisting and spreader to swing, which greatly reduces the working efficiency of the crane. For lifting equipment and the handling industry with frequent loading and unloading, it is imperative to reduce the swing time of the spreader and improve work efficiency. In addition, the swinging of heavy objects can also pose a great safety hazard to the operator, the work site and the crane itself. Therefore, researching an anti-sway system for industrial cranes to achieve stable operation and smooth operation has become a hot issue for crane manufacturers and research institutions. A good anti-sway system can play a good anti-sway effect, can improve labor productivity, and eliminate potential safety hazards in the production process.

Anti-sway technical features:

1. The anti-sway function can prevent the hook from swinging due to the inertia impact of the crane running under the load of the crane and trolley.

2. Anti-sway function can realize anti-sway in the whole range of lifting height

3. The anti-sway function independently sets a knob for the height of the load, which can choose different heights according to the height of the load, which can more accurately control the rope length of the load and the swing angle.

4. The anti-sway function can control the swing angle within ±0.25 degrees.

5. The anti-shake function has a separate switch on the operator for whether to activate this function or not

6. The anti-sway function allows the operator not to manually adjust the angle of the control swing, which can improve the stability and accuracy of the entire handling process.

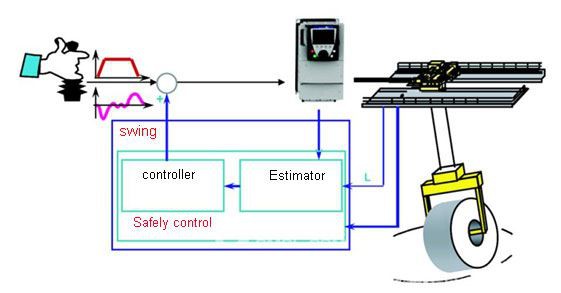

The principle of anti-sway control of European crane

Anti-sway control uses the pendulum principle to continuously limit the swing by modifying the speed command signal sent to the electrical control system. The swing angle is calculated by checking the lifting height of the hook, and then the swing angle is offset by the given acceleration and deceleration. Brings the object to a set speed or sway little or no sway.

The advantages of European crane anti-sway technology:

1. Stable - effectively reduce material swing

The European crane with anti-sway function can solve the problem of reducing the swing time of the spreader and improving the work efficiency. In addition, the European-style crane's operating frequency conversion technology for large and small trolleys can realize the micro-speed function. The micro-speed function can realize the load control more accurately, and convert the large movement of the joystick into a slow and precise load movement. This smart feature helps the operator control the load more precisely, increasing the safety of the action.

When the anti-shake is not put in: the shaking is serious when starting, stopping, accelerating and decelerating. Swing distance of the workpiece is about ±80cm, and it takes a long time for the workpiece to stand still. It is impossible to stably move from one station to another in a short period of time.

When anti-sway is put in: start, stop, accelerate and decelerate slightly, and the swing distance is ±1.5cm. It can be hoisted and transported according to the original technical process.

2. Fast - effectively improve work efficiency

Due to the continuous expansion of industrial production scale, the increasing production efficiency, and the gradual increase in the proportion of material handling costs in the production process, the demand for large-tonnage industrial cranes continues to grow. Under the requirements of large lifting capacity, high work grade system requirements and fast work speed:

When the customer does not invest in the anti-sway of the crane: it takes about 200 seconds to accurately place the hanging object in the designated position;

When the anti-sway is put in: place the hanging object in the designated position precisely, which can save at least 20-30% of the time.

3. Accurate - accurate positioning

When the industrial crane completes the hoisting of large molds or other large and heavy goods, it is required to realize the function of inching to realize the transportation of materials to an accurate position. The European crane with anti-sway function can accurately realize this function. Inching, also known as jogging, provides a method of approaching a load's destination with high precision. Can be used for both hoisting and horizontal operation. The "Inching Range" can be preset from 2 to 100 mm. Install the anti-sway system, the system has a precise inching function, which can accurately transport the material to the exact position. When the load placement requires very precise, using this function can improve productivity and safety.