inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980

inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980Henan Kino Cranes Co., Ltd

No.730, Xinghai Center, Hongqi District, Xinxiang, Henan, China

Tel: +86-373-3809941

M/P: +86-15993036980

E-mail: inquiry@kinocranes.com

Official Website: www.kinocranes.com

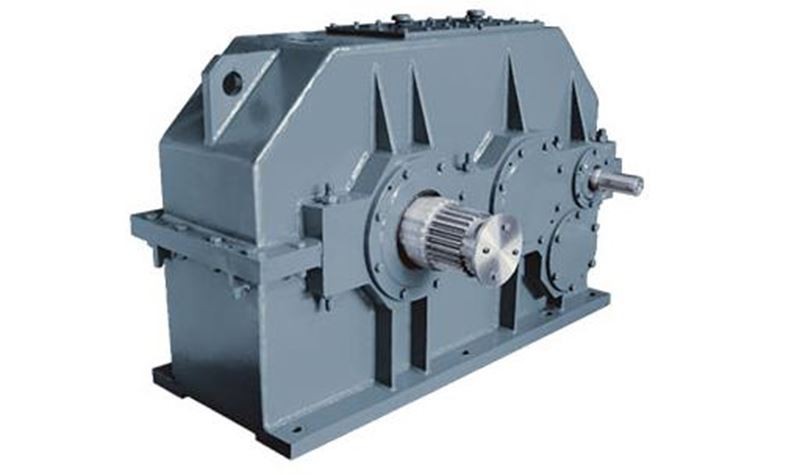

The reducer for crane is developed on the basis of the medium hard tooth surface reducer. Reducer QY series reducer includes QYS type (three fulcrum) and QYD type (base type) two series of hard tooth surface reducer for cranes. It has three types: three-level, four-level and three-four level combined. The reducer for cranes is welded with steel plates, the box is annealed to relieve stress, the gears are made of high-quality low-carbon alloy steel, and the tooth surfaces are carburized and quenched, and processed by grinding. The product quality is stable and the performance is reliable.

Features:

1. Compact structure, small size and light weight

2. High efficiency, low noise and low vibration

3. Increase the transmission center distance and reduce the height of the whole machine to meet the requirements of the running mechanism.

4. Higher operational reliability and enhanced transmission power

5. Long oil change interval, reducing maintenance costs

The main technical parameters:

Type: Parallel shaft drive

Transmission stage: 3 to 4

Speed ratio range: 16~400

Power range: 1.1 ~ 3500kw.

Considering the working characteristics and transmission ratio range of crane mechanisms, further improving product performance, and adopting fewer specifications to meet various requirements of users, the characteristics of KINOCRANES' reducer are:

1) High loading capacity. The gears are processed by carburizing, quenching and grinding. The loading capacity is greatly improved compared with the soft tooth surface and medium hard tooth surface gear reducer of quenched and tempered hobbing.

2) Small size and light weight. Compared with the reducer with soft tooth surface and medium hard tooth surface, the same bearing capacity reducer can reduce 2-4 equivalent frame sizes.

3) High efficiency, low noise and small vibration. The gear grinding process has improved the accuracy level, and the gears have been trimmed. The comprehensive efficiency of each gear stage is 0.98, and the vibration and noise are significantly reduced.

4) Adopt multi-stage number and reduce single-stage speed ratio. The center distance can be opened to reduce the height of the reducer to meet the requirements of crane various mechanisms; the maximum nominal transmission ratio of the reducer reaches 400, which meets the requirements of slow-speed cranes.

5) The three-point reducer can be installed vertically, horizontally, or even deflected at a certain angle, which is convenient and flexible.

6) This series of reducers has a combination of three and four stages (ie, three-stage assembly type, four-stage transmission ratio), which provides the premise for the universal of slow-speed cranes.